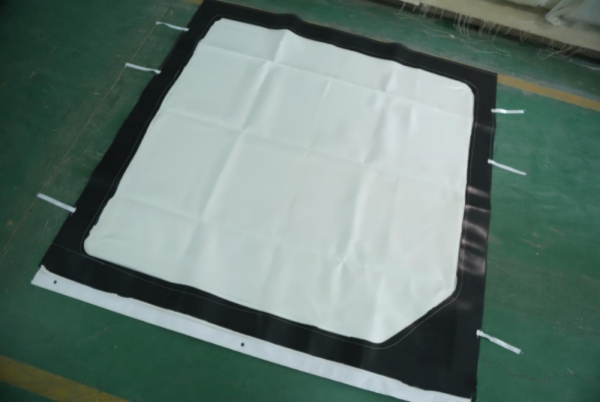

High-capacity filter press cloth is often used in traditional horizontal filter presses. The filter cloth produced by Bolian especially is applied in high-capacity filter press filters, also known as vulcanized filter cloth or glue-hanging filter cloth. High-capacity filter press filter is a new type of horizontal filter press, with characteristics of low filter cake moisture content, high degree of automation and good washing performance.

Filter cake moisture content has a great relationship with the sealing of the filter cloth. According to the characteristics of high-capacity filter press filters, this press filter cloth developed and produced by Bolian carries out the special process of vulcanization on the sealing surface of the filter cloth, which improves the seal reliability, effectively avoids shotcrete, and ensures the low moisture content of the filter cake.

Characteristics of high-capacity filter presses filter cloth

Natural rubber is used for the vulcanized surface of the filter cloth.

The rubber is tightly bound to the filter cloth by vulcanization. The rubber surface has a certain thickness and softness, which plays a good sealing role, thus, when the filter blows back, there will be no leakage, so the wind energy can work properly on the materials and improve the blowing efficiency. In addition, natural rubber is more environmentally friendly, has no pungent odor, and has a higher vulcanization strength than synthetic rubber.

Reduce the moisture content of the filter cake.

Under the same conditions, the vulcanized filter cloth has better sealing performance and higher blowing efficiency, so the moisture content can be less than 15%.

Save energy, reduce consumption and improve productivity.

By using the vulcanized filter cloth, the filter machine has lower energy consumption and higher efficiency. If there is air leakage or the wind can not all act on the filter cake, in this case, it will cause a waste of wind energy, leading to damage to the filter plate and filter cloth, and the phenomenon of mine running, which increases the cost of operation and maintenance.

Long service life.

Under continuous operation, the average service life of vulcanized rubber integrated filter cloth is 45-60 days, which is 30% -50% longer than that of the ordinary filter cloth, greatly improving the working efficiency of the filter machine and reducing the labor intensity.

Wide applications.

As a professional filter cloth supplier, Bolian provides high-quality vulcanized cloth which is widely applied in copper concentrate, nickel concentrate, gold mine tailings and other working conditions.