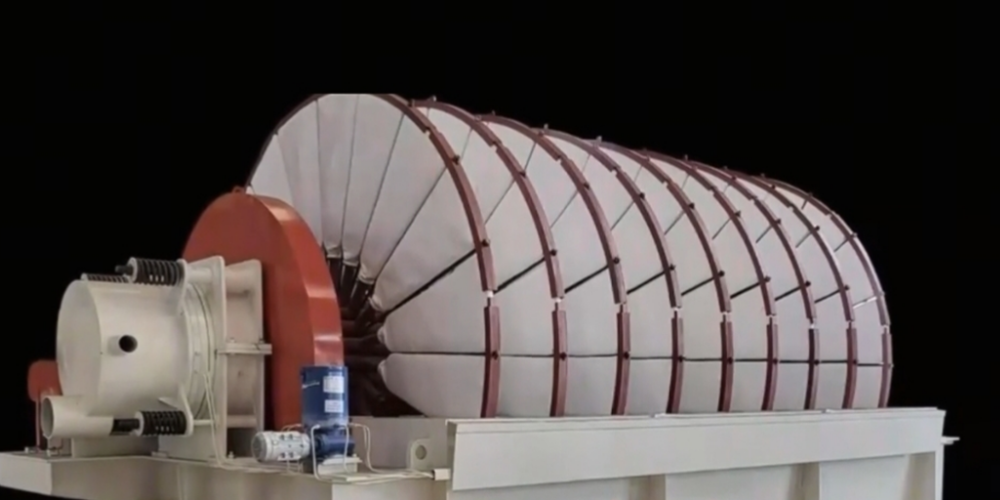

Disc filter cloth is the core filtration medium of disc filters. Its selection directly affects filtration efficiency, filter cake moisture, and equipment stability. Choosing the right filter cloth is key to improving performance and reducing operational costs.

Polyester: Acid- and weak alkali-resistant with good abrasion resistance.

Polypropylene: Excellent resistance to strong acids and alkalis, strong hydrophobicity, ideal for highly corrosive environments.

Nylon: Superior abrasion resistance, high strength, and good elasticity, though its chemical resistance is lower than polyester and polypropylene.

Monofilament: Smooth surface, uniform pore structure, easy cake release, suitable for high solid content applications.

Multifilament: Higher filtration precision and better filtrate clarity, but less effective in cake release.

Filtration accuracy: Should match the particle size distribution and process requirements.

Water permeability: Affects throughput—new cloths have high permeability, but clogging must be considered during operation.

Cake formation: The ability to form a stable and easily detachable cake layer quickly and evenly on the filter surface.

Cake release: Monofilaments perform better; surface smoothness is key.

The cloth must have sufficient strength, dimensional stability, abrasion resistance, and low elongation to withstand installation tension, material wear, and temperature variations during long-term use.

Choosing the right disc filter cloth requires a comprehensive evaluation of material properties, filtration precision, permeability, cake release performance, mechanical durability, and equipment compatibility. Sample testing and technical communication with a professional filter cloth supplier are highly recommended.

Bolian offers high-performance, durable, and customized disc filter cloths tailored to customer-specific conditions—helping improve filtration efficiency, reduce cake moisture, and ensure continuous, stable operation.