Electrolytic diaphragm fabric is a critical component in the electrolysis process, serving as a separator between the anode and cathode to prevent direct mixing of cations and anions while facilitating electrolyte transfer. The primary functions of electrolytic diaphragm fabric include:

The primary role of electrolytic diaphragm fabric is to isolate the generated cations and anions in the electrolytic cell, preventing their direct contact and ensuring the stability of the electrolyte and the normal progression of the electrolytic reaction.

The diaphragm fabric possesses a certain permeability, allowing ions in the electrolyte to pass between the anode and cathode. This is essential for maintaining ionic balance and current transfer during electrolysis.

By effectively isolating and guiding ion transfer, the diaphragm fabric enhances the efficiency of the electrolysis process. High-performance diaphragm fabric reduces energy loss, making the electrolytic reaction more economical and efficient.

In some electrolytic processes, the reactions at the anode and cathode produce different products. If these products mix, they may adversely affect the entire process. The diaphragm fabric effectively prevents such mixing, maintaining the purity of the electrolysis products.

A stable permeability rate effectively controls the flow of electrolyte, preventing leakage, overheating, and other abnormal conditions. This complies with safety production standards while reducing waste liquid discharge.

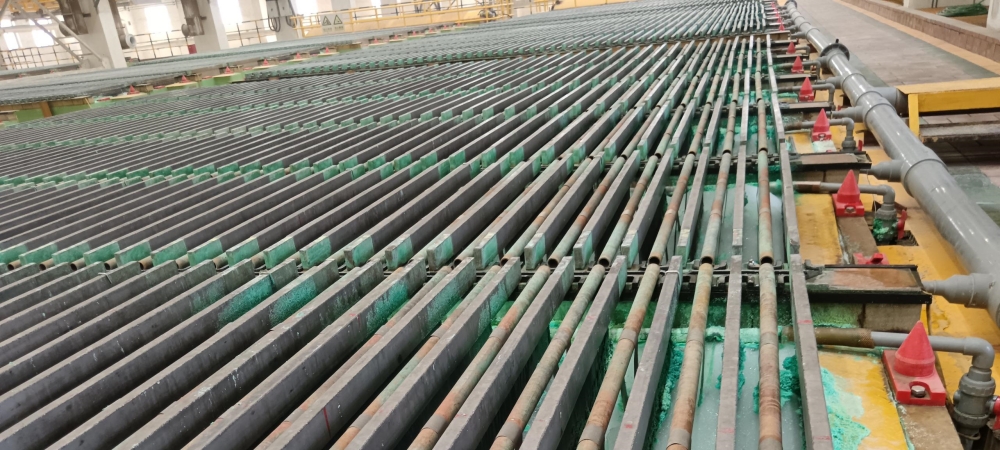

Bolian Electrolytic Diaphragm Fabric is specifically designed for non-ferrous metal electrolytic refining and is suitable for all working conditions in sulfide and chloride systems. As a professional filter fabric manufacturer, We provide customized solutions tailored to different requirements.