Industrial filter cloth is widely used in liquid-solid separation and industrial dust collection, serving as an essential filtration medium in industries such as chemicals, mining, pharmaceuticals, food processing, environmental protection, and non-ferrous metals.

Ensure flat contact between the filter cloth and the filter plate edges: The parts of the cloth that are compressed by the filter plates must be flat and wrinkle-free to prevent damage or slurry leakage from uneven pressure.

Check for foreign objects: Make sure there are no large sludge particles or foreign materials between the filter cloth and the filter plates during installation. Such objects can damage the plates or the cloth when compressed.

Pay attention to filter cloth orientation: Filter cloths typically have a designated "slurry-facing side" (usually the calendered or smoother surface). Unless specified otherwise, install the cloth with the calendered surface facing the slurry. Incorrect installation may cause clogging and reduce filtration efficiency.

Avoid over-tightening buckle straps: Over-tightening the filter cloth can trap residual sludge in the compression area of the plates, which cannot be automatically cleaned and may affect filtration performance.

Store spare filter cloths properly: Keep spare cloths in a cool, dry environment shielded from direct sunlight. Use dark-colored covers to protect against UV exposure, which accelerates material degradation and reduces cloth lifespan.

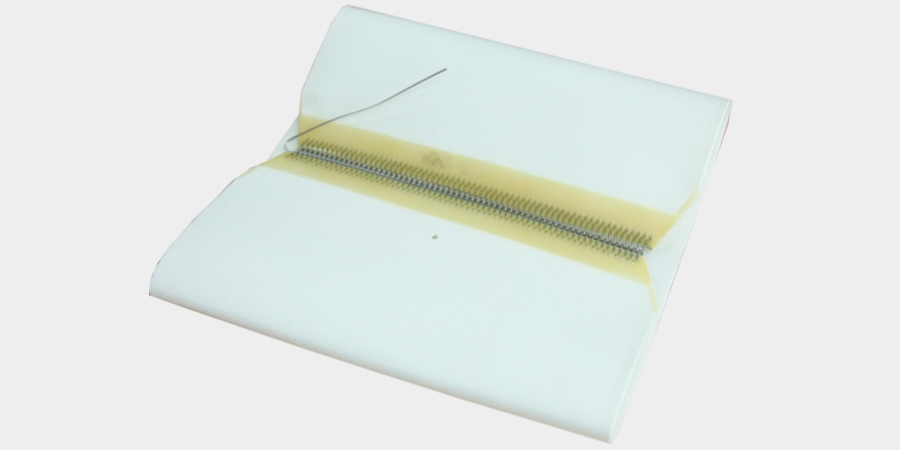

Install a support filter cloth first: Before installing the main filter cloth, install a support cloth. Its function is to reduce abrasion between the filter cake and the raised surface of the filter plate during cake discharge, protecting the main filter cloth and extending its service life. This also improves the overall filtration effect. The support cloth can be installed similarly to chamber filter cloth.

By following these installation guidelines, you can ensure that your industrial filter cloth performs optimally and lasts longer.