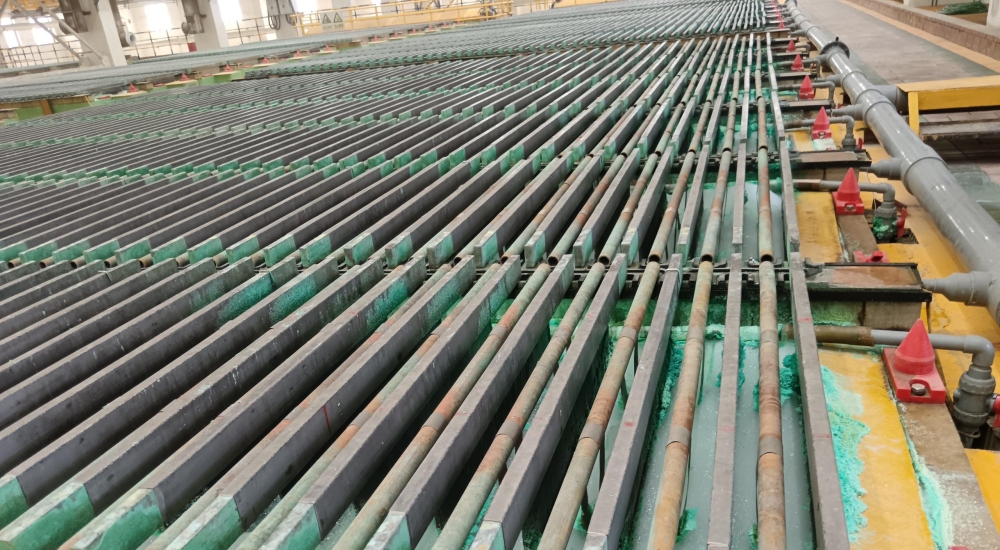

In response to the characteristics of sulphurisation and chlorination systems, BOLIAN has developed a range of membrane products. In sulphurisation systems, the cathode liquid must be separated from the anode liquid to avoid excessive hydrogen ions. The cathode plate is therefore enclosed in a bag, which allows the nickel cathode liquid to enter through a pipe and maintains the liquid level inside the bag 3–5 cm higher than the level outside.

Low resistivity, precise water permeability, and guaranteed liquid level difference.

The oxygen produced by the anode causes a large amount of acid mist to overflow. Therefore, the oxygen and acid mist are collected in an anode bag and channelled through a liquid pipe. This prevents the anode liquid from seeping back into the cathode area and ensures that the anode liquid level is 3–5 cm lower than the cathode liquid level.

Based on experience with chlorination systems, improvements have been made to the original sulphurisation system. These improvements enable precise water permeability and stronger corrosion resistance, which effectively improves the service life of the filter cloth and the quality of the plate output.

During the chlorination process, chlorine gas is produced at the anode. As chlorine gas is highly toxic, it must be collected to prevent leakage. This process therefore uses anode bagging technology, which involves placing the anode plate in an anode membrane bag. This ensures that the anode liquid does not seep back into the cathode area and cause environmental pollution.

The diaphragm materials developed by BOLIAN effectively reduce uneven thickness, pores, granulation and liquid injection rupture in nickel plates, thereby improving their grade. The diverse product range includes general-purpose, low-permeability, high-permeability, low-resistance and corrosion-resistant types, allowing for flexible selection based on on-site working conditions.