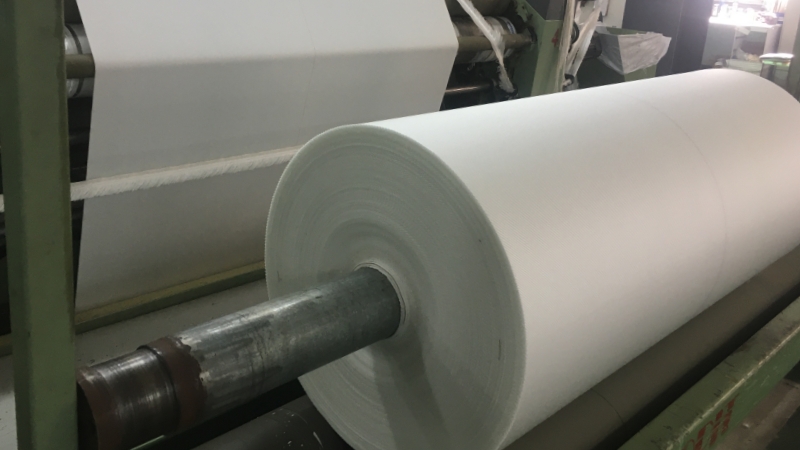

The nature of the filter fabric in industrial processes directly affects the filtering efficiency of a filter press equipment. Both the quality of the filter cloth and the level of processing are indispensable. One of the main factors affecting industrial filter cloth performance is the choice of raw materials. Good cake release properties, non-shrinkage, and dimensional stability are essential—features found in embedded filter cloths, coated filter cloths, edge-wrapped designs, and perforated cloths. The service life of a filter cloth is influenced not only by material wear but also by its performance under continuous production conditions. The value of industrial filter cloth is particularly evident in applications such as non-ferrous metal smelting, mineral processing, and sludge dewatering.

These excellent properties have enabled industrial filter cloths to be widely used across various industries, addressing challenges caused by poor cake release and extending their reusability. To enhance filtration precision, new filter cloths woven with monofilaments, monofilament-reinforced backing, and metal clip connections have been adopted.

As the important part of a filter press, industrial filter cloths must be washed regularly. They are typically medium-thickness woven fabrics designed to withstand acidic or neutral filtration liquids. Maintaining open and unobstructed filter cloth pores is key to ensuring the efficient operation of a filter press.

The most fundamental requirement of industrial filter cloth is its solid particle retention capability. Filter cloths made of staple fibers or multifilament yarns generally have better particle retention, which is a major factor influencing their performance during use.

Bolian is a manufacturing enterprise integrating design, R&D, production, and sales. It mainly produces technical textiles such as horizontal vacuum belt filter fabrics, tower press filter cloths, filter press cloths, electrolytic diaphragm cloths, and FGD filtration filter cloth for power plants. Bolian provides full-process technical support: pre-sales needs analysis, in-process usage tracking, and after-sales problem-solving for filter cloth applications.