1. Material Innovation

Aerospace-Grade Polymers: Made from high-crystallinity polyester (PET) or nylon 6 (PA6) monofilaments.

Molecular Orientation Reinforcement: Melt-stretching aligns molecular chains → Tensile strength ↑ 40% (compared to traditional multifilament).

Precision Diameter Control: 0.15–0.35 mm ultra-thick monofilaments

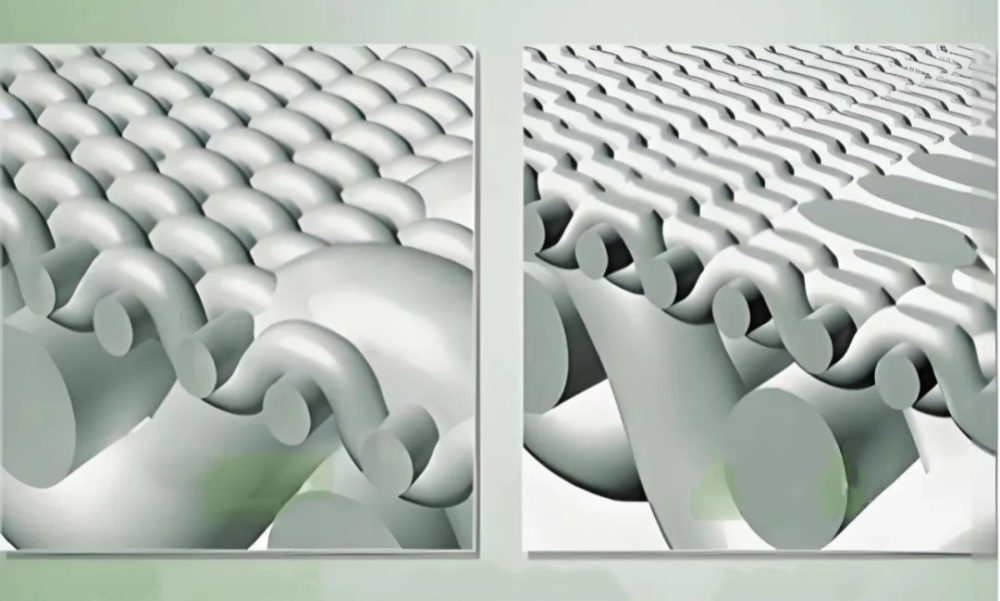

2. Weaving Structure

1. Physically Smooth Surface

Monofilament advantages:

Zero fuzz fibers → Eliminates anchoring points for filter cake.

Mirror-like smoothness (Ra ≤ 0.2 μm) → Friction coefficient ↓ 60%.

Comparative Test:

Clay filter cake peel-off force: Monofilament cloth only 0.3 MPa, Multifilament cloth 0.8 MPa.

Cake Release: Ultra-smooth, anti-adhesion surface layer.

Strength: Tear-resistant middle layer + cushioning base.

Permeability: Quick-drain bottom layer.

Extended Service Life:

Acid & Alkali Resistance: pH 1–14

UV Aging Resistance: > 5000 hours

Smart Maintenance:

Reversible surface contamination cleaning (restore with direct high-pressure water jet).

Tailored Solutions:

Particle Size Distribution → Optimized monofilament diameter.

Slurry Viscosity → Customized surface energy parameters.

Equipment Type → Adjusted weaving tension.

By combining material-level genetic engineering with structural innovation, monofilament filter cloth transforms the contradiction between “high strength” and “easy cake release” into a synergistic advantage—marking a breakthrough in industrial filtration.