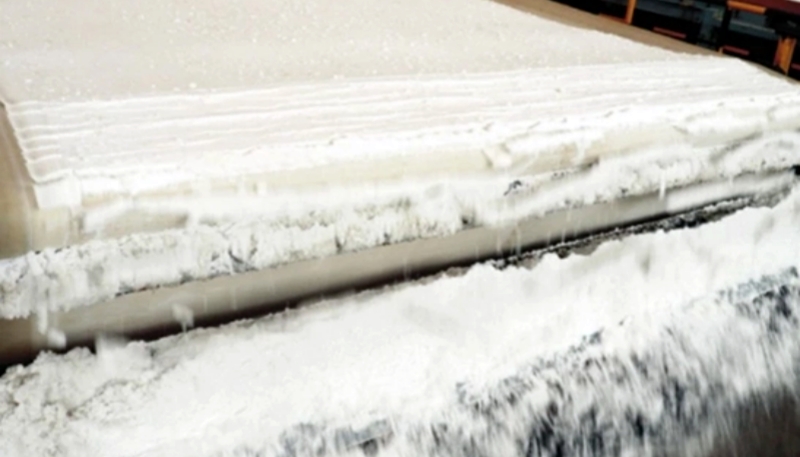

In phosphogypsum treatment, dewatering is a critical step. Polyester monofilament filter cloth, combined with vacuum horizontal belt filters (high-efficiency solid-liquid separation equipment), plays an essential role in the dewatering process and is widely applied in the phosphate chemical industry.

Polyester monofilament filter cloth uses vacuum suction to effectively separate solid particles from liquid in phosphogypsum slurry. The solids remain on the filter surface while liquid is extracted, significantly reducing the moisture content for easier subsequent processing.

During filtration, the cloth effectively retains harmful elements such as phosphorus, fluorine, and heavy metals, reducing their release into the environment. Through filtration and washing, harmful impurities in phosphogypsum are further minimized, enhancing its safety.

Phosphogypsum treated with polyester monofilament filter cloth has lower moisture content and fewer impurities, making it more suitable as a raw material for construction materials or agricultural soil conditioners. This enhances the resource utilization value of phosphogypsum.

By minimizing the liquid discharge from phosphogypsum slurry, polyester monofilament filter cloth prevents wastewater containing hazardous substances from contaminating soil and water. Additionally, the separated solid phosphogypsum is easier to handle, reducing waste accumulation and environmental impact.

Using polyester monofilament filter cloth significantly improves filtration efficiency, reduces labor and processing time, and lowers energy consumption. This translates into substantial cost savings for phosphogypsum treatment plants.

Polyester monofilament filter cloth delivers high-efficiency separation, reduces impurities and energy consumption, minimizes pollution, and lowers processing costs—providing strong support for resource recycling and sustainable production in the phosphogypsum industry.