The vertical automatic filter press utilizes high-pressure squeezing and high-pressure air drying to extract filtrate from material, achieving solid-liquid separation. It integrates washing, dewatering, and air-drying functions. The machine uses only one piece of filter cloth, which is a continuous loop.

Core filter cloth requirements:

Abrasion resistance, tensile strength, elongation at break, edge finishing, joint strength, filtration precision, thickness, etc.

The horizontal vacuum belt filter is a continuous industrial solid-liquid separation device. It uses a sliding seal between a looped rubber drainage belt and a fixed vacuum box to accelerate filtration through vacuum suction while maintaining high separation efficiency.

It features high filtration efficiency, large production capacity, excellent washing performance, and easy maintenance.

Core filter cloth requirements:

Air permeability, anti-clogging performance, joint strength, pore uniformity, crease resistance, etc.

The plate and frame filter press is a widely used filtration device. It consists of alternately arranged filter plates and frames mounted on a sliding support. Each frame is rectangular and hollow, including types such as washing plates, non-washing plates, and intermediate frames.

Core filter cloth requirements:

Tensile strength, elongation, surface flatness, air permeability, etc.

Vertical leaf filters are widely used for fine filtration in industrial processes. These efficient machines are applied in sugar production, alumina refining, vanadium extraction from steel slag, and other chemical industries, with a high degree of automation.

Core filter cloth requirements:

Filtration precision, backflushing recovery rate, hygiene grade (for food industries), etc.

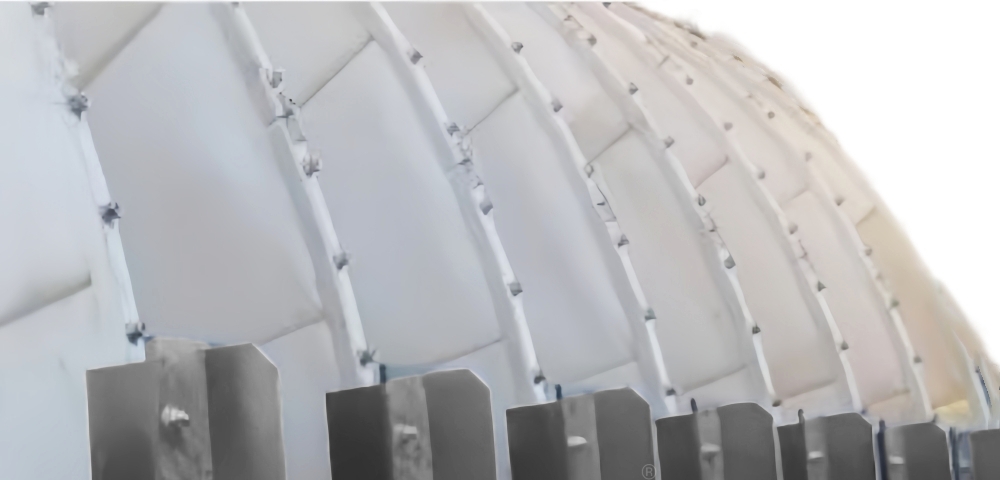

Rotary drum filters operate continuously with negative pressure as the driving force. The filtration surface is on the cylindrical drum. Initially used in the alkali and mining industries, rotary drum filters are now also applied in chemical processing, coal preparation, and sludge dewatering.

Core filter cloth requirements:

Filtration precision, abrasion resistance, pore size stability, hygiene grade (for food industries), etc.

Different types of filtration equipment require different filter cloth properties. The optimal filter cloth must be selected based on the equipment's features, working conditions, and material characteristics.