The higher the filtration rating, the lower the air permeability; conversely, the higher the air permeability, the lower the filtration rating.

Filtration Rating refers to the size of the smallest particles that a filter fabric can effectively retain, typically measured in microns (µm). It represents the fabric's "screening" capability.

High Filtration Rating: Means the fabric's pores are very small, allowing only tiny particles or liquid to pass through, thus capturing fine impurities.

Low Filtration Rating: Means the fabric's pores are larger, allowing bigger particles to pass and only intercepting large impurities.

Air Permeability refers to the volume of air passing through a unit area of the filter fabric per unit time under a specified pressure difference. It indicates how easily air passes through the fabric, reflecting its "openness."

High Air Permeability: Air passes through easily, with low resistance, potentially leading to lower energy consumption and faster filtration speeds.

Low Air Permeability: Air has difficulty passing, resulting in high resistance, requiring more power and higher energy consumption.

Pore Size: Fabrics with a high filtration rating have smaller pores formed by weaving or needling. Smaller pores offer greater resistance to airflow, naturally resulting in lower permeability. Conversely, larger pores mean higher permeability.

Porosity: This is the proportion of total volume occupied by pores. Even with the same nominal pore size, fabrics with finer fibers or tighter construction may have lower porosity, reducing air permeability. High-precision fabrics often achieve their rating through higher fiber density, which sacrifices porosity and lowers permeability.

1. Fiber Material & Surface Treatment

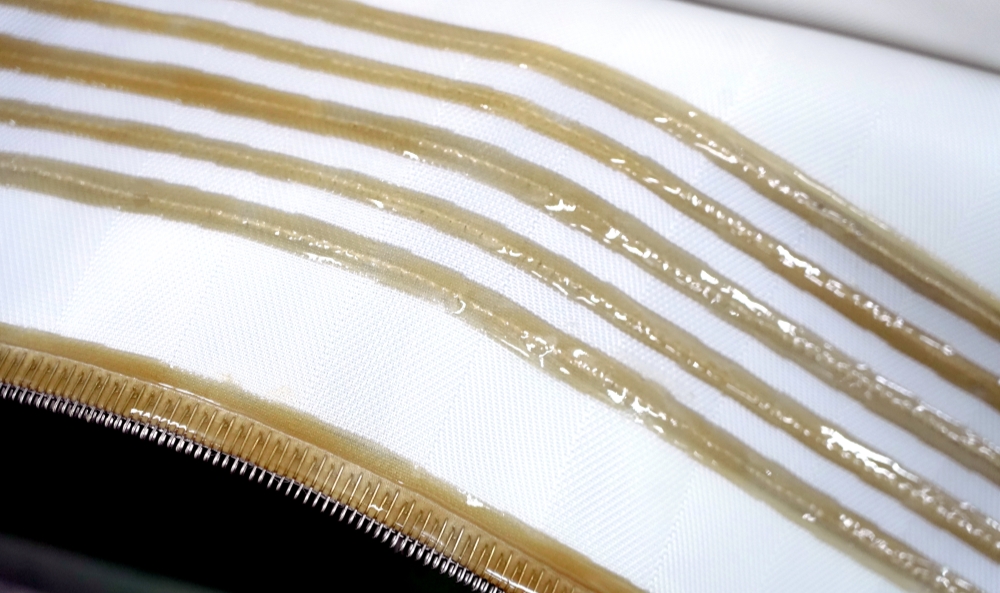

Different materials have varying surface characteristics, smoothness, and hydrophilicity/hydrophobicity, affecting fluid flow. Treatments like calendering, coating, or laminating alter the relationship between permeability and rating.

2.Structure Design:

Weaving Method: Plain, twill, and satin weaves create different pore structures and permeability.

Non-Woven Methods: Materials like needle felts or meltblown fabrics form complex 3D filtration paths; even with identical nominal ratings, their permeability can differ significantly from woven fabrics.

Differing Measurement Standards: Filtration ratings are defined and tested using various standards, as is air permeability.

Therefore, selecting a filter fabric is a comprehensive technical decision. It requires balancing filtration rating (desired separation outcome), air permeability, material compatibility, mechanical strength, and the characteristics of the material being filtered.