Sludge dewatering is a critical step in the wastewater treatment process. Its primary objective is to reduce the moisture content of sludge, thereby decreasing its volume and weight and ultimately lowering transportation and disposal costs. In this process, sludge dewatering belts play a vital role. However, during actual operation, dewatering equipment often encounters various issues, such as belt misalignment, high cake moisture content, and belt damage. Identifying and resolving these problems in a timely manner is essential to ensure the stable operation of the entire sludge treatment system.

Belt misalignment mainly occurs when the dewatering belt deviates from its normal running track during operation, which can lead to reduced dewatering efficiency and even equipment damage.

The following measures can be taken to address this issue:

First, inspect and adjust the belt tensioning device to ensure proper tension, avoiding misalignment caused by excessive looseness or tightness.

Second, regularly clean sludge residues attached to the surface of the sludge dewatering belt to maintain cleanliness and reduce the risk of belt deviation.

Finally, check the sensitivity of the belt tracking system to ensure it can promptly correct the belt position during operation and maintain stable performance.

High cake moisture content not only increases the difficulty of subsequent treatment but also prevents effective reduction in sludge volume and weight.

Effective solutions include:

First, optimizing the sludge conditioning process by adding appropriate conditioning agents to improve sludge dewaterability.

Second, adjusting dewatering machine operating parameters, such as sludge feed rate, pressing pressure, and running speed.

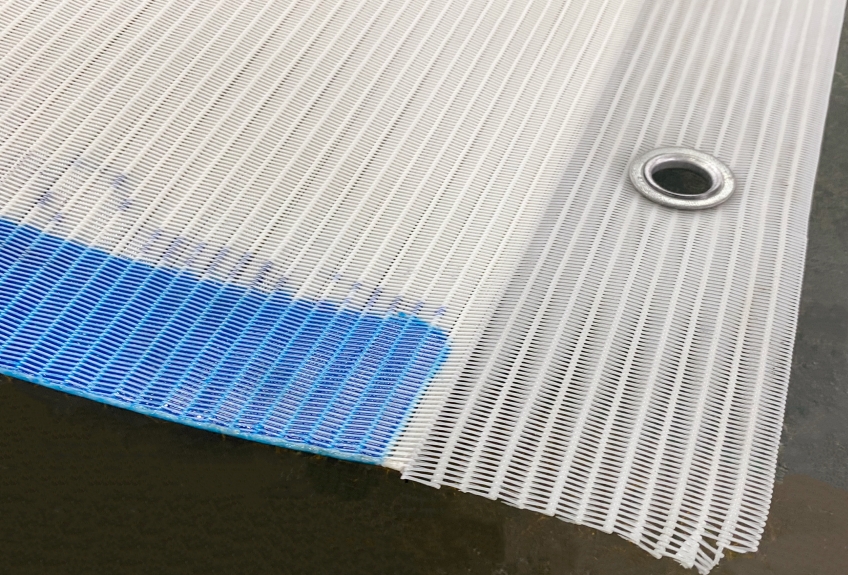

Third, regularly inspecting the wear condition of the sludge dewatering belt and replacing aged or damaged belts in a timely manner to maintain optimal dewatering efficiency.

Belt damage can lead to operational interruptions and even equipment failure. Therefore, when purchasing dewatering belts, it is essential to choose reputable manufacturers to ensure product quality and performance. At the same time, daily inspections should be strengthened, and damaged belts should be replaced promptly to prevent minor issues from escalating into major failures.