Bolian successfully developed its first vertical filter press cloth in 1994, designed for international equipment brands such as LAROX, ROXIA, and Pneumapress, as well as all types of vertical filter presses in China. Over the past 30 years, this product has gained widespread recognition from users worldwide.

A vertical filter press—also known as a fully automatic filter cloth is widely used for the filtration of starch, nickel concentrate, alkali residue, copper concentrate, and similar materials. Through high-pressure squeezing and air-blow drying, the equipment efficiently separates solids and liquids by forcing filtrate out of the slurry. It integrates three key functions: washing, dewatering, and air drying. With high-pressure extrusion and airflow dewatering technology, the moisture content of the filter cake can be reduced to as low as 10%–15%.

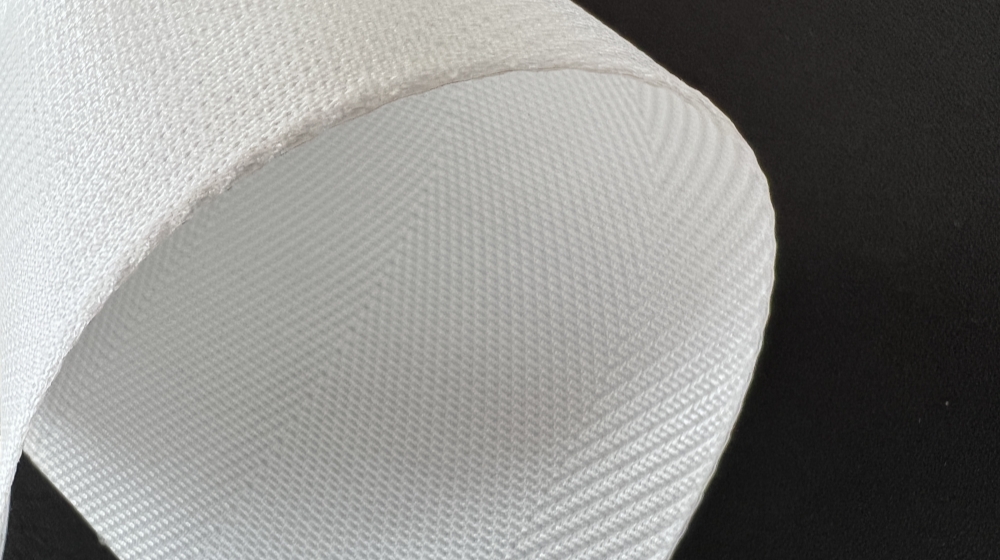

Accurate particle capture: Advanced weaving and controlled pore size allow micron-level precision, effectively retaining target particles and ensuring clear filtrate or pure solids.

Efficient separation, easy cake discharge: The smooth surface enables fast, complete cake release, minimizing residue and clogging, significantly improving discharge efficiency and equipment utilization.

Tear and tensile resistance: Manufactured with high-strength synthetic fibers and advanced weaving technology, the cloth withstands high pressure, tension, and mechanical abrasion, offering long service life.

Excellent dimensional stability: Maintains stability under continuous wet-dry cycles and pressure variations, preventing excessive shrinkage or elongation.

Corrosion-resistant: Multiple material options are available to suit different working conditions, enabling resistance to acids, alkalis, solvents, and various chemicals—ideal for harsh environments.

Optimized fabric structure: Engineered yarn arrangement and weave pattern create open channels that reduce deep clogging risks.

Easy to clean and regenerate: Smooth surface prevents particle embedding, allowing fast and simple cleaning, repeated reuse, and reduced replacement frequency.