In the solid-liquid separation process, the vertical filter press plays a crucial role, and the filter cloth is one of its core components. Once the cloth is damaged, it will not only affect filtration efficiency but may also cause the press to stop running. Therefore, understanding the causes of filter cloth damage, as well as the correct handling and replacement methods, is essential for ensuring production stability and efficiency.

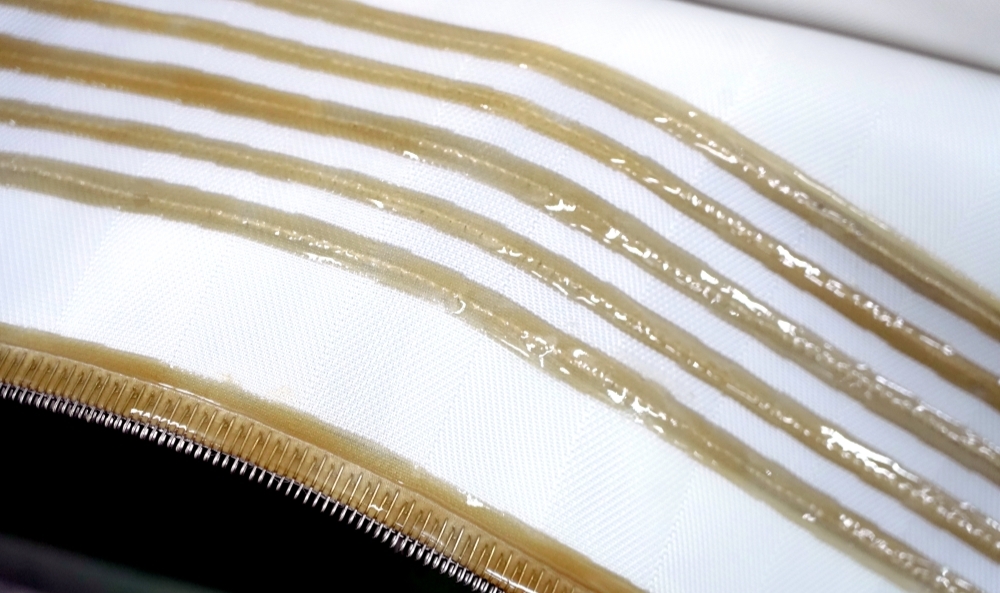

Poor quality filter cloth

Filter cloth is woven from fibers. If the fiber material is of poor quality or not suitable for the working conditions, it may easily lead to damage, broken seams, or wear.

Improper operation

Incorrect operating methods, such as excessive feeding pressure or non-standard procedures, can cause premature filter cloth damage.

Unsuitable material characteristics

Different materials require different types of filter cloth. If the material being filtered contains sharp or abrasive particles, and the cloth material does not match, it will accelerate wear or even cause perforation.

Before operation, the filter presses and cloth should be carefully inspected. If a filter cloth is found to have a hole or broken seam, it is generally difficult to repair while maintaining sealing and filtration precision. Especially in high-precision solid-liquid separation applications, once the cloth is damaged, the most reliable solution is to replace it immediately with a new filter cloth to ensure proper filtration performance and stable operation.

Filter cloth is a consumable part and should be replaced regularly, even without visible damage. The replacement cycle is not fixed and depends on factors such as:

The type and properties of the material being filtered

The working frequency and production capacity

The required filtration precision

In most cases, the service life of a tower press filter cloth is 3–6 months. Even without damage, it is recommended to replace it every 3–6 months. For heavy workloads, if filtration efficiency declines significantly, the replacement should be carried out earlier.

As a professional industrial filter fabric manufacturer, Bolian provides a wide range of high-performance filter cloths suitable for vertical filter presses, helping customers improve filtration efficiency and meet production demands.