After clarifying the material characteristics and equipment conditions, the final selection of a filter cloth should focus on the technical details of the product itself. The performance of double-layer monofilament filter cloth is determined by its materials, structural design, and post-treatment processes.

Material selection is fundamental to defining the chemical resistance, temperature tolerance, and mechanical strength of filter cloth. Common monofilament materials include polyester (PET) and polypropylene (PP). Polyester offers high mechanical strength and good acid resistance but may hydrolyze in strong alkaline environments. Polypropylene has broad chemical stability and is resistant to both acids and alkalis, but its temperature resistance is comparatively lower. When choosing filter cloth, it is necessary to refer to the chemical properties of these materials.

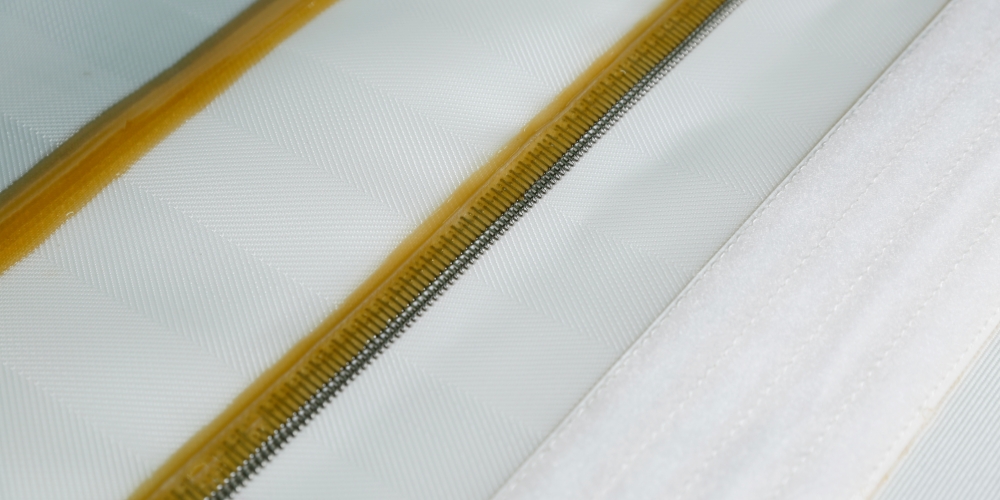

The double-layer design consists of a filtration layer and a support layer. The interlaced construction enhances mechanical strength and stability. This structure provides high strength, low deformation, and smoother surfaces—especially after calendering—which improves cake release. Monofilament diameter, weave pattern, and pore size determine initial filtration precision, cake discharge efficiency, and resistance to clogging. The smooth surface of filter fabrics reduces particle adhesion, enabling cleaner and more thorough discharge.

Grammage (weight per square meter) and thickness are key indicators of the density and contaminant-holding capacity of filter cloth, influencing filtration precision as well as air and water permeability.

Post-treatment processes such as heat setting and calendering further optimize performance. Heat setting improves dimensional stability and reduces shrinkage during use, while calendering smooths the surface, minimizes fiber fuzz, and enhances cake release and cleaning efficiency.

In summary, the performance of double-layer monofilament filter cloth depends on the precise coordination of material selection, structural design, and finishing processes. By optimizing these parameters, manufacturers can achieve higher filtration accuracy, better mechanical stability, and improved cake discharge. Understanding these technical factors helps industries enhance filtration efficiency, extend filter cloth lifespan, and reduce operational costs.