In modern industrial production, the efficiency and stability of the filtration process directly impact product quality and production costs. Whether in mining, chemical processing, food production, or environmental protection, choosing the right filter cloth is often the key to improving overall efficiency. However, different process conditions, material properties, and equipment types mean that a “universal” filter cloth rarely meets all needs. That’s where customized industrial filter fabrics become the most efficient and economical solution.

We provide a wide range of customized industrial filtration products designed to precisely adapt to complex demands across various industries:

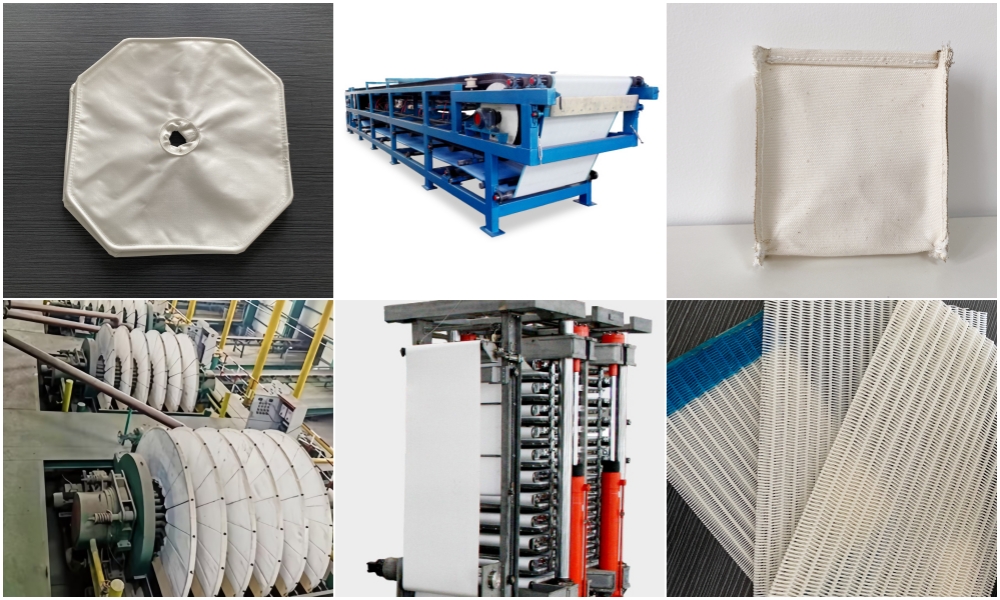

Horizontal belt filter cloth – Ideal for continuous filtration operations, featuring excellent tensile strength and wear resistance for long-term stable performance.

Tower press filter cloth – High filtration accuracy, achieving fine filtration of 3-5 μm, High strength, with a 1% elongation limit, improving dewatering efficiency and reducing filter cake moisture content.

Filter press cloths – Optimized for different plate structures and material characteristics, enhancing filtration precision and strength.

Electrolytic diaphragm bags(Anode Bag and Canode Bag)– Used in electrolytic processes, offering outstanding chemical resistance and and available in different specifications.

Dust collector bags – Suitable for high-temperature, corrosive environments, ensuring efficient dust separation and collection.

Polyester filter belts – High strength and abrasion resistance, widely applied in washing, dewatering, and material handling.

Drum filter cloths – Designed for rotary drum filters, with optimized surface design and pore structure to increase filtration speed and regeneration efficiency.

With our customized solutions, you can:

Improve filtration efficiency – Adjust fabric material, pore size, and structure based on particle size, viscosity, and chemical properties of the material to significantly enhance speed and accuracy.

Solve common problems – Effectively reduce clogging, wear, short service life, and difficult cake discharge, minimizing downtime and maintenance costs.

Lower operating costs – Extend filter cloth service life, reduce replacement frequency, and optimize filtration to cut down on energy consumption and waste treatment costs.

No matter if you face high temperature, strong corrosion, or ultra-fine filtration, we provide expert technical support and flexible production solutions. From material selection (polyester, polypropylene, nylon, PPS, PTFE, etc.) to weaving technology (monofilament, multifilament, nonwoven, etc.), we ensure a perfect match for your equipment and process requirements.

Contact us today for your best customized filtration solution – helping you achieve more efficient, economical, and stable industrial production.