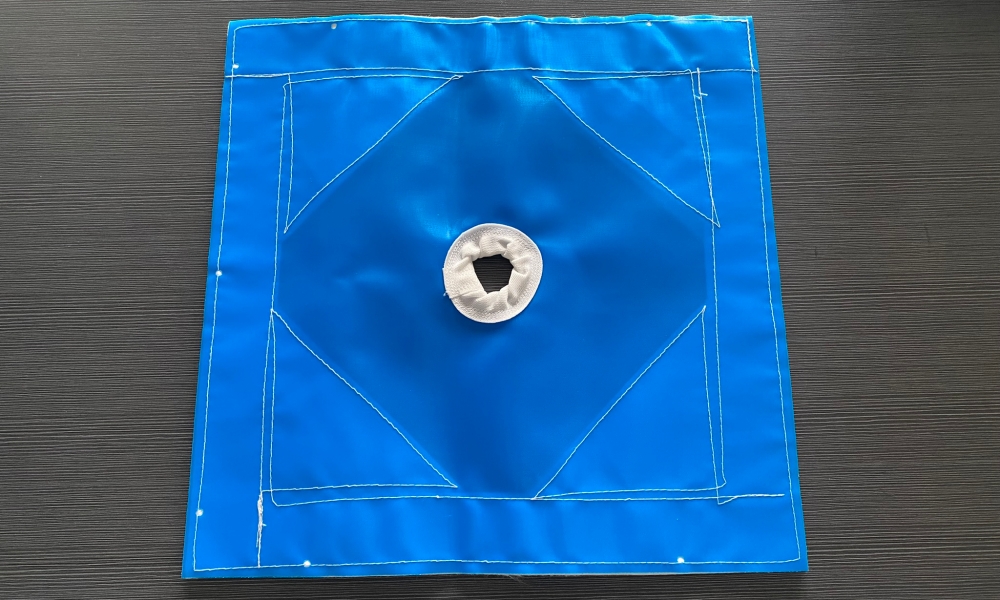

In industries such as chemical processing, metallurgy, and pharmaceuticals, solid-liquid separation is a critical factor affecting product quality and production costs. Plate and frame filter presses are widely used due to their high filtration pressure and high solid content in filter cakes. As the core component of the system, the filter cloth plays a decisive role in separation performance. Below is a brief introduction to a reliable choice that performs exceptionally well under demanding operating conditions — nylon monofilament filter cloth for plate and frame filter presses.

Excellent Mechanical Strength

Nylon (polyamide) fibers are known for their high tensile strength and outstanding wear resistance. When manufactured as monofilaments, the structural strength is significantly superior to that of multifilament or staple fiber fabrics, enabling the filter cloth to withstand the high pressures generated during the pressing stage of plate and frame filter presses.

Stable Chemical Resistance

This filter cloth offers good resistance to acids and alkalis, making it suitable for corrosive media commonly encountered in chemical processing, metallurgy, and wastewater treatment applications, ensuring stable and reliable operation.

High Permeability

The smooth surface of monofilament fibers results in uniform and open pore structures. An effective filter cake forms quickly at the initial filtration stage, producing clear filtrate. High flow rates are maintained throughout the entire filtration cycle, significantly improving dewatering efficiency.

Smooth Surface for Easy Cake Release

Thanks to the smooth monofilament surface, filter cakes do not easily adhere to the cloth. During discharge, cakes can be released cleanly and completely, reducing downtime and improving operational efficiency.

Chemical and Metallurgical Industries

Used for filtering pigments, metal hydroxides, catalysts, and other materials, with excellent resistance to acidic and alkaline environments.

Pharmaceutical Industry

Meets stringent requirements for filtration precision and cleanliness.

Mining and Mineral Processing

Applied in coal washing, sand washing, and mineral separation processes to effectively separate coal slurry and tailings.

Environmental Protection & Wastewater Treatment

Ideal for municipal sludge and industrial wastewater dewatering, producing filter cakes with high solid content.

Like all materials, nylon monofilament filter cloth has its application limits. The recommended long-term operating temperature is below 120°C. In higher-temperature environments or in the presence of strong oxidizing agents, suitability should be carefully evaluated, or alternative high-temperature-resistant materials should be considered.

In summary, nylon monofilament filter cloth has become an essential filtration medium for filter presses due to its excellent wear resistance, broad adaptability, high permeability, and easy cake release. In production environments where efficiency and cost control are critical, choosing this reliable filtration material helps ensure stable equipment operation and consistent filtration performance.