In the nickel mining and processing, filter cloth plays a critical role as a key filter material, covering processes such as concentrate dewatering, tailings treatment, and electrolytic refining.

High-performance filter cloth not only improves production efficiency but also ensures the long-term, stable operation of filtration equipment.

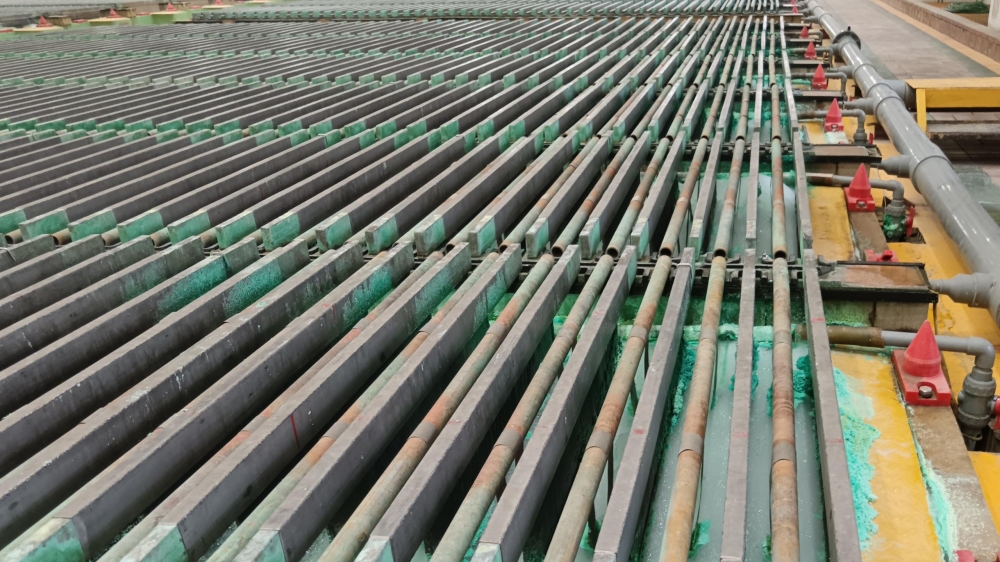

Bolian vertical filter press cloth has been successfully applied to LAROX vertical filter presses used by large overseas nickel mining company. It demonstrates stable and reliable filtration performance in the smelting and slurry processing of nickel ore, copper, nickel, cobalt and other non-ferrous metals.

Manufactured from high-quality polypropylene multifilament yarns, Bolian vertical filter press cloth offers excellent resistance to acids, alkalis. It operates reliably under working temperatures of 60–70 °C, effectively reduces cake moisture content, and improves overall production efficiency. Through calendering surface treatment, the cloth surface becomes smoother, significantly reducing clogging and improving cake discharge, further enhancing filtration performance.

In electrolytic nickel production, electrolytic diaphragm bags are essential filtration materials for maintaining stable operation and ensuring product quality. Installed in electrolytic cells, diaphragm bags isolate impurities and solid particles generated during electrolysis, preventing their migration and protecting the quality of nickel deposition on the cathode. They also stabilize electrolyte flow and improve current distribution, enabling uniform nickel ion deposition and higher cathode nickel purity.

Bolian electrolytic diaphragm bags are mainly used in nickel sulfate electrolysis systems, effectively maintaining a stable liquid level difference and ensuring smooth, continuous operation for the production of high-quality electrolytic nickel. To meet diverse operating conditions, Bolian offers a wide range of diaphragm bags, including standard, low-permeability, high-permeability, low-resistance, and corrosion-resistant types.

Selecting high-performance filter cloth tailored to specific applications not only improves efficiency and reduces operating costs but also helps nickel producers meet increasingly stringent environmental requirements. As demand for higher purity and sustainability continues to grow, material upgrades and customized filter cloth solutions will become a key development trend in the nickel industry.