With increasingly stringent environmental regulations, flue gas desulfurization (FGD) systems have become a critical solution for emission reduction in power generation, metallurgy, and chemical industries. As a professional supplier of industrial filtration fabrics, Bolian has been deeply engaged in the filtration industry for many years, providing stable and efficient filtration solutions for the FGD sector. Our main products include dust filter bags and belt filter fabrics.

In wet flue gas desulfurization and dust collection systems, filter bags are continuously exposed to high humidity, elevated temperatures, and corrosive acidic gases such as SO₂ and SO₃. Bolian offers customized dust filter bags manufactured from a wide range of materials, including polyester, PPS, PTFE, aramid, and fiberglass, to meet different operating requirements.

Among them, PPS, PTFE, and aramid filter bags demonstrate excellent resistance to acids, high temperatures, and chemical corrosion, ensuring long-term and stable filtration performance even under severe desulfurization conditions. Bolian filter bags are designed to match dust collector cages and cleaning systems precisely, delivering high filtration efficiency and good air permeability. Special surface treatments effectively reduce bag blinding and dust buildup, significantly extending service life and reducing maintenance frequency.

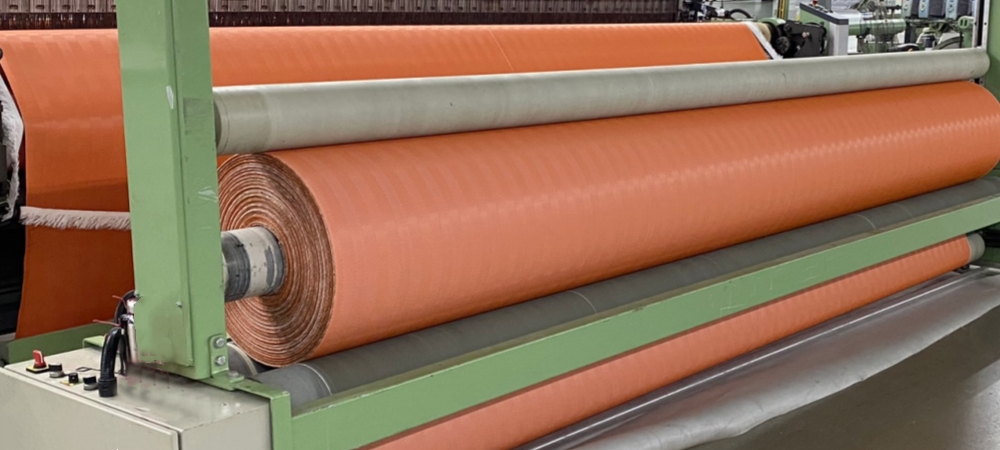

In the wet FGD process, belt filter fabrics play a vital role in solid-liquid separation. Bolian belt filter fabrics are produced using high-density weaving on German-imported equipment, offering excellent dimensional stability and resistance to deformation. Made primarily from high-quality polyester monofilament, these fabrics provide outstanding abrasion resistance, corrosion resistance, and heat resistance, with a typical service life of six months or longer under normal operating conditions.

These belt filter fabrics ensure efficient solid-liquid separation, improve gypsum dewatering efficiency, and support continuous, stable operation of desulfurization systems. They are essential filtration components for achieving sulfur dioxide emission reduction and meeting environmental protection standards.

Bolian provides customized solutions. Through customized design and manufacturing, our filtration fabrics help FGD systems achieve higher efficiency, longer service life, and lower operating costs, supporting both environmental sustainability and economic performance.