In power plant flue gas desulfurization (FGD) systems, the filter cloth used on horizontal vacuum belt filters acts as the system's “gatekeeper.” It directly affects gypsum purity, filtrate clarity, and the stable operation of the entire process. Selecting the right filter cloth can significantly improve desulfurization efficiency and solid–liquid separation performance. Conversely, improper selection often leads to poor filtration results, increased equipment wear, and even unplanned shutdowns.

Higher filtration accuracy is not always better. A filter cloth with overly small pore size can produce clean gypsum cake and clear filtrate, but it also tends to clog quickly. This increases vacuum pressure, raises energy consumption, and requires frequent cleaning, all of which shorten the service life of the cloth. On the other hand, pores that are too large may cause solid loss, negatively affecting gypsum quality and wastewater treatment. The ideal filtration accuracy is determined by the actual particle size distribution of desulfurization gypsum, achieving an optimal balance between retention efficiency and permeability for long-term, stable high throughput.

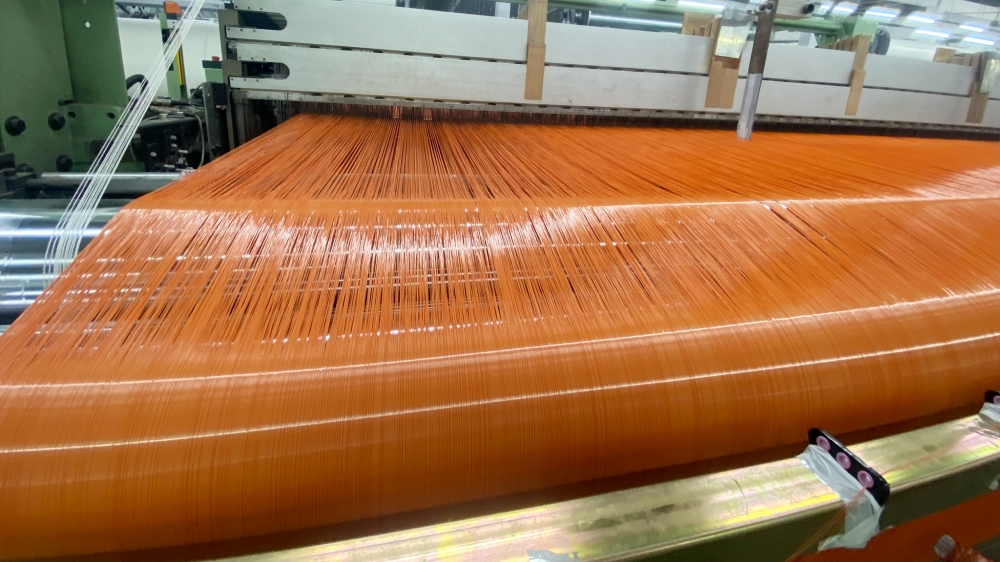

During operation, filter cloths are exposed to both mechanical and chemical stresses. Mechanically, they must maintain structural integrity under continuous vacuum suction and repeated cake discharge, making abrasion resistance critical to service life. Chemically, the cloth must withstand sulfuric acid, sulfites, and various oxidizing compounds without fiber degradation. Any loss of strength or pore structure change caused by corrosion will directly affect filtration performance.

Final filter cloth selection is the result of comprehensive evaluation of filtration performance, mechanical strength, and chemical resistance. In addition, ease of installation, cleanability, regeneration performance, and the supplier's technical support should all be considered.

Although small in size, desulfurization filter cloths play a crucial role in ensuring stable operation, controlling operating costs, and meeting environmental regulations. They are not simple consumables, but a technical investment. Instead of frequent reactive replacements, careful initial selection and communication with experienced technical teams can ensure long-term, efficient, and economical operation of power plant desulfurization systems.