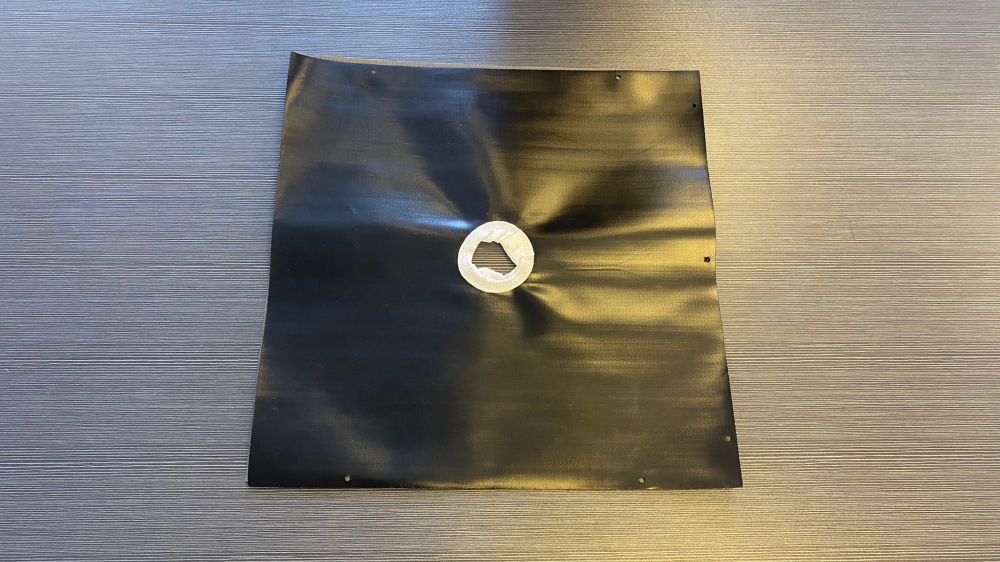

Today, we focus on a filter medium that plays an important role in the solid–liquid separation industry — polypropylene mono-multifilament press filter cloth.

Yarn structure: Combines the characteristics of both monofilament and multifilament yarns, typically woven together within the same filter cloth.

Key characteristics:

Monofilament yarn helps improve filtration accuracy and surface smoothness

Multifilament yarn provides good strength and wear resistance

Achieves a balance between filtration performance and mechanical durability

The calendered surface offers excellent cake release performance. Filter cakes are easier to detach from the cloth surface, reducing adhesion and clogging, which improves cleaning efficiency and supports continuous operation. At the same time, the material maintains stable permeability, ensuring a good balance between separation efficiency and filtration speed.

Polypropylene mono- multifilament plate and frame filter cloth is widely used in many industries. In chemical processing, it is used for separating various materials; in metallurgy, it supports the recovery of valuable metal particles; in pharmaceuticals, it helps ensure product purity; in ceramics manufacturing, it assists in slurry treatment; and in environmental protection, it plays a key role in wastewater and sludge treatment.

In today’s industrial environment where efficiency and sustainability are increasingly important, selecting the right filtration material is both a technical and economic decision. With its balanced overall performance, polypropylene mono-multifilament plate and frame filter cloth helps ensure filtration quality while reducing maintenance frequency and replacement costs.

As industrial technology continues to advance, performance requirements for filtration materials keep rising. With its balanced properties and broad applicability, this filter cloth remains a reliable and efficient choice for improving production efficiency and product quality. In the future, such essential filtration materials will continue to play a vital role in separation technologies and support refined, sustainable industrial development.